2026 FEATURED EQUIPMENT

Demo Day Equipment Showcase – Study Up Before

APPLICATION EQUIPMENT | GRINDERS | SHREDDERS | SCREENERS | WINDROW TURNERS | SUPPORT & SITE EQUIPMENT

APPLICATION EQUIPMENT

Express Blower

Bark Blower

EB-60HO

The Express Blower EB-60HO is the most powerful PTO-driven blower truck available, delivering 1500 CFM at 20 PSI for exceptional material placement performance. With 15 additional cubic yards of capacity compared to the TM-45MD and a weight reduction of 8,000 pounds, it offers greater payload efficiency and more revenue per job. The EB-60HO also features increased ground clearance, modern LED box lighting, and an optional 250-gallon water system for added versatility. And with no auxiliary engine to maintain, operators benefit from reduced upkeep and easier service. This high-output model is engineered to maximize productivity, profitability, and reliability on every project.

Jason Wedmore

jwedmore@expressblower.com

800-285-7227

Finn Corporation

Material Blower

MBM3

The all-new Finn MBM3 Material Blower is redefining compact blower performance with greater capacity, smarter handling, and easier seasonal use. Designed as a next-generation upgrade to the legendary BB302, the MBM3 features a larger 3-yard hopper for longer run times and a raised airlock skid, a first for Finn, offering greater flexibility for mounting on flatbeds or trailers. Integrated fork pockets and a single-point lift streamline installation and removal, even with a small crew. Operators also benefit from an upgraded control panel, improved radio remote, anti-plug system, a 27-gallon fuel tank providing up to 12 hours of runtime, a lightweight EcoStrike® hose, and a 150′ hydraulic reel that boosts efficiency on the job. Optional additions such as a front feed chute, work lights, and dust suppression kits allow crews to tailor the unit to their needs. Compact, capable, and built for productivity, the MBM3 makes mulch installation, erosion control, and property maintenance faster and easier.

Cory Yamaguchi

cyamaguchi@finncorp.com

714-316-3137

Finn Corporation

Material Blower

MBH6

Redesigned with contractors in mind, the FINN MBH6 Material Blower delivers strong productivity, added value, and customer-driven enhancements. Built on a Tier 4 Final design with patent-pending features, it’s engineered to make every job easier and every hour more productive. The MBH6 emphasizes simplicity and reliability with a streamlined control system featuring multi-language capability and durable, easy-to-service components. Ideal for bark, mulch, compost, and soil blends, it performs consistently across challenging terrain, even in wet conditions. Its mid-size footprint makes it easy to operate, maintain, and troubleshoot, ensuring maximum uptime. For accessing tight or difficult areas, the MBH6 excels, helping contractors improve efficiency and profitability on every project.

Cory Yamaguchi

cyamaguchi@finncorp.com

714-316-3137

GRINDERS

Astec Industries

Horizontal Grinder

Peterson 5710E

The Peterson 5710E horizontal grinder is the newest tracked horizontal grinder in the Astec line.

The 5710E is designed for high-volume producers who require frequent moves among sites. The 5710E features a ground fuel option, improved approach angles, a 4,515 square-inch screening area and an 8% larger rotor with more bits. The machine weight is also lighter than its predecessors.

Powered by a Tier IV Caterpillar C27 1,050 hp (783 kW) engine or an optional C32 1,125 hp (839 kW) engine, the 5710E can easily tackle a variety of materials, having a positive impact on efficiency and productivity.

Michael Spreadbury

mspreadbury@astecindustries.com

541-255-6376

CBI & Ecotec: Terex Brands

Grinder

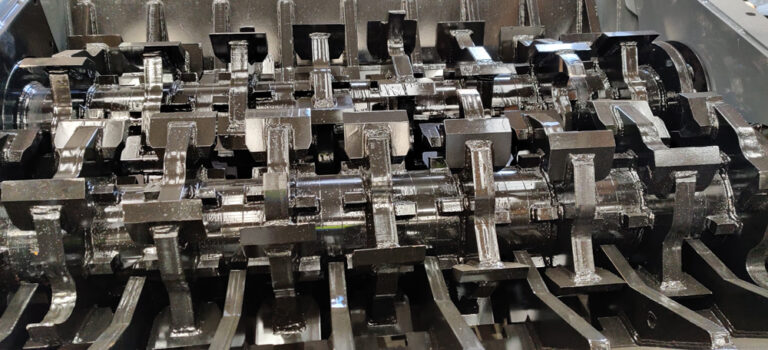

6400CT

The CBI Magnum Force 6400CT Horizontal Grinder is an extreme-duty machine built for high production in demanding composting and organics operations. Whether processing green waste, storm debris, logs, brush, stumps, pallets, or contaminated wood, this yellow monster delivers exceptional resilience and throughput. Its fully welded, line-bored hog box ensures maximum durability when breaking down tough feedstocks for efficient composting.

The revolutionary “cassette-style” clam shell design allows operators to swap rotors faster than any grinder in its class—cutting changeover time in half. Easily switch between grinding and chipping to handle diverse organic materials and meet varying compost specifications. With four interchangeable rotors, the 6400CT adapts to shifting markets and keeps composting sites running at peak performance.

Nathaniel Fuller

nathaniel.fuller@terex.com

603-702-0504

https://www.terex.com/cbi/en/product/horizontal-grinders/6400ct

Ecoverse

Grinder

Redback DS1125 T

When high throughput and production are essential, especially with tough materials, this reliable and powerful machine is the perfect choice.

The Redback DS1125T can handle everything you feed it, thanks to its CAT® C32 1125 hp (895 kW) Tier 4 Final diesel engine. Its feed control system automatically adjusts to maximize throughput, and its grinding components are extremely resistant to damage by contaminants – meaning more uptime, more production, and more material processed.

The Redback DS1125T will amplify your output and productivity.

Dan Delciappo

daniel.delciappo@ecoversesolutions.com

440-937-3225

Morbark, LLC

Grinder

3400XT Horizontal Grinder

Listening closely to customer feedback while developing the design for the 3400XT Wood Hog, Morbark provides the features customers want and the versatility they need, while staying true to our proven technology. Like all of Morbark Wood Hog models, the 3400XT also is available with electric power. The size of the 3400XT allows the model to be configured for multiple applications and global markets without additional design considerations.

Morbark Sales

989-866-2381

Morbark.inquire@inquire.com

www.morbark.com

Rotochopper

Grinder

L II Horizontal Grinder

With serious horsepower and a rugged design shaped by real-world demands, the Rotochopper L II — the newest and largest horizontal grinder in our lineup — was designed to redefine performance. From a high-wear infeed and thicker screens to its single-pivot powerfeed, the L II is built for durability and throughput. And with enhanced controls, smarter diagnostics, and 18″ of ground clearance, you’ll stay productive in even the toughest conditions. Backed by our uncompromising commitment to quality, the L II is more than a machine—it’s where power meets performance.

Rotochopper Sales

contact@rotochopper.com

320-875-9950

Tigercat Industries Inc.

Grinder

Tigercat 6900

The Tigercat 6900 is a heavy duty upswing horizontal grinder designed for high throughput mulch production and material reduction. With Tigercat’s legendary build quality, the 6900 is designed for extreme duty and long life, utilizing only the highest quality components. The upswing rotor and large infeed opening with outward wing walls maximize processing capacity. The grinder’s upper frame pivots on the undercarriage, allowing the operator to adjust the infeed angle or discharge height for different material lengths. The adjustable angle eliminates the need for outriggers. The pivoting upper frame allows transport on an 18-inch lowboy trailer without the need to fold the discharge conveyor. The machine has remote control functions for simple operation and mobility on site, along with an easy-to-use 10-inch display screen for machine monitoring and function adjustment. Learn more at www.tigercat.com/product/6900-grinder.

Kevin Selby

kselby@tigercat.com

519-753-2000

Vermeer

Grinder

HG6800TX

Built for land-clearing and pipeline right-of-way operations, the HG6800TX horizontal grinder offers a high-horsepower engine on a tracked machine with a compact design. Featuring 950 hp (708 kW) in a 92,000 lb (41,730.5 kg) class, and an infeed design designed specifically for feeding larger materials such as whole trees and large stumps, the new grinder is built to power through tough materials with less operator interaction.

Ted Dirkx

tdirkx@vermeer.com

Vermeer

Grinder

HG4000TXG2

The HG4000TX combines innovative technology and proven design with options such as the Vermeer coloring system and productivity monitoring system, that exceed customer expectations. Built for aggressive performance and high capacity, this tracked machine has industry-leading features that contribute to its dependability, efficiency and durability.

Ted Dirkx

tdirkx@vermeer.com

Viably

Grinder

Diamond Z DZH6000

The DZH6000 is a best-selling high-capacity horizontal grinder, delivering up to 1,200 HP, rapid screen changes, and unmatched reliability for virtually any grinding application.

Viably Compost Expert

hello@thinkviably.com

720.890.9090

https://thinkviably.com/resource-library/press-release-viably-named-distributor-for-diamond-z-grinders-in-southwest-us/

Viably

Grinder

Komptech Lacero 8010

The Komptech Lacero 8010 is a high-speed, horizontal grinder with a powerful 812 HP CAT® diesel engine that delivers high-volume production with maximum mobility for wood waste, green waste, biomass, mulch, and organic waste operations.

Viably Compost Expert

hello@thinkviably.com

720.890.9090

SHREDDERS

Ecoverse

Shredder

Doppstadt Inventhor 9

The INVENTHOR Type 9 high-torque shredder is cutting-edge in every way, from the drive train concept to the hopper function, and it has completely redefined the high-torque, slow-speed shredder concept. Track it into position, fold out the conveyors, and let this shredding beast handle your most challenging applications.

German engineering, heavy-duty construction, and top-quality components provide the reliability and efficiency needed for relentless day-to-day operations and a long service life.The INVENTHOR Type 9 is a powerful, robust machine made for primary volume reduction with wood waste, municipal solid waste, industrial waste, green waste, construction & demolition waste, and more.

In short, the Doppstadt INVENTHOR Type 9 is as good as shredders get.

Sara King

sara.king@ecoversesolutions.com

440-522-3783

EDGE Innovate

Shredder

EDGE VS420

The EDGE VS420 is a high-capacity, high-torque twin-shaft shredder that is widely used for processing a variety of organic materials, including green waste and compost. EDGE’s next generation shredder has been developed for ultimate versatility and high resistance to contaminants with a number of customisable shredding programmes and chamber configurations available. An intelligent operating system which incorporates tramp metal protection provides the ultimate protection from contaminants and prevents asset damage.

Lee Williamson

lee.williamson@edgeinnovate.com

205-777-9987

www./edgeinnovate.com/products/vs420/

Product Video: https://www.youtube.com/watch?v=XyXRE7Spfcc

Eggersmann North America Inc.

Shredder

Eggersmann Z 60

The Simple Shredder with the Unique Variety of Applications. Able to make a specified and consistent end product in just one pass if required.

The wide range of applications with the new generation of Eggersmann universal shredders is impressive and almost endless. The Eggersmann series machines are as efficient as possible, able to shred waste wood, roots, green waste, logs, C&D waste, commercial waste, MSW, or even tires, plastics, mattresses or batches of special material and more.

30 tools are mounted to the 10 ft. long shredding rotor. The counter comb is equipped with 19 teeth. Its simple and sturdy design enables a quick and flexible variation of the distances between the rotor tools and the counter comb tools. Depending on the requirements, different setting options are available to react to the desired size of the finished product.

After passing the counter comb, the material falls onto the discharge conveyor. As an option, the machine can be equipped with a screen basket. In that case, the shredded material first falls onto this screen basket, which encloses the lower half of the rotor. The size of the finished product can additionally be adjusted with the screen basket.

Thanks to the double-bolt locking the risk of losing it is very unlikely and changing the, is very easy. The (Standard) Multigrip teeth are perfect to shred wood waste, green waste, MSW, C&D waste, commercial waste, plastics or even railroad ties, while the Rootgrip teeth are specially designed to shred green waste and roots only.

Maria Cargould

maria@eggersmann-na.com

646-210-9029

Shred-Tech

Shredder

MRW 1.300g

The Pronar MRW 1.300 slow-speed high torque shredder is a single-shaft heavy-duty shredder machine intended for pre-shredding of green organic waste, wood, biomass, paper, plastics and films, small scrap, or bulky waste. Offering a single 21 or 42 knife configuration with counter knives and sieve, the MRW 1.300 is unquestionably one of the best single-shaft shredders available. Other core features include: a Volvo Penta 12.8l engine with 550HP (405kW), incredible maneuverability, easy-change bolt on knives, and a large hopper. The shredder also has a maximum throughput of up to 120 tons per hour.

3r Sales

sales@3rmachinery.com

1-800-465-3214

Vermeer

Shredder

LS3600TX

The single-shaft LS3600TX is the first slow-speed shredder from Vermeer, featuring exclusive innovations that efficiently process contaminated waste streams and help protect critical machine components. Unparalleled access to the rotor, comb, and engine compartment solves long-time industry maintenance issues.

Ted Dirkx

tdirkx@vermeer.com

SCREENERS

Ecoverse

Screener

Doppstadt SM 720.3

Always working on their next innovation, Doppstadt’s market leading SM 720 trommel has been reborn! The SM 720.3 is a streamlined version of the bestselling Doppstadt SM 720, taking the machine back to it’s roots: a powerful engine with no DEF, a simple and intuitive control system, and extremely robust construction. And, this next generation trommel has added smart features and options that cement Doppstadt’s legacy as the true innovator in mobile trommel screens.

Dan Delciappo

daniel.delciappo@ecoversesolutions.com

440-937-3225

EDGE Innovate

Screener

EDGE TRM831

The largest wheeled mounted trommel screen in North America, the EDGE TRM831 trommel screen offers unmatched screening capacity with its massive 31-foot-long screening drum. Designed for high-volume operations, it delivers precision, efficiency, and durability, making it ideal for applications such as compost, soil and mulch.

Lee Williamson

lee.williamson@edgeinnovate.com

205-777-9987

eFACTOR3

Screener

Ecostar Hextra T 70003F

Ecostar offers innovative disc screening solutions, both stationary and mobile, designed to separate even the most difficult compost, whether dry, wet or sludgy. The screening machines process compost into homogeneous sizes ranging from 10 to 100mm with a high production capacity of up to 100 T/H.

Ecostar screens are powered by the patented Dynamic Disc Screening (DDS) technology, that minimizes wrapping and clogging, reducing machine downtime, cleaning and maintenance costs. They are equipped with hexagonal / octagonal discs in Hardox, low-consumption 7.5 kW electric motors, delivering outputs of 20T/H and energy savings of up to 70% compared to traditional technologies.

Thanks to the modular design of the Hexact stationary screen and the operational flexibility of the Hextra mobile screen, these compact yet robust machines can be easily customized to meet specific operational needs while requiring minimal space. The Hextra mobile screen can operate with 100% electric power or Diesel generator and features a patented sliding SMART HOPPER able to switch from 3 fractions to 2 fractions screening in just 1 minute. Equipped with a dosing auger, the smart hopper allows operation in a loop with all shredders.

John Gregory

jgregory@efactor3.com

1-704-944-3232

Eggersmann North America Inc.

Screener

Eggersmann S 60

The Eggersmann S 60 three-fraction star screen is able to screen compost, mulch, waste wood and wood chips with a production of up to 400 cy/h. It comes standard with cleaning elements and the industry leading QuickChange screening shafts. The unique SplitSpeed fines deck with its 5 independent electric motors allows for a wide variety of different screening sizes. The S 60 is available as diesel over electric or 100 % electrically driven.

Maria Cargould

maria@eggersmann-na.com

646-210-9029

Eggersmann North America Inc.

Screener

Eggersmann T 60

The Eggersmann T 60 trommel screen is designed for customers with particularly high production requirements. It offers the remarkably precise separation efficiency typical of all Eggersmann screens with a screening capacity of up to 265 cy per hour. This makes it a high-class mobile screening solution.

Maria Cargould

maria@eggersmann-na.com

646-210-9029

Shred-Tech

Screener

Pronar MPP 1238s

This powerful machine, with two decks, precisely separates materials into three fraction sizes. Touchscreen-adjustable speeds and easily adjustable screening box inclination enable seamless fine-tuning for specific material types. The 136 HP 3.6-liter engine efficiently handles heavy loads without high revolutions. The vibrating box lifting system and side tensioning of decks ensure quick access and a brief setup.

3r Sales

sales@3rmachinery.com

1-800-465-3214

https://3rmachinery.com/pronar-mpp-1238s-scalper-screen/?searchid=186&search_query=MPP#images-1

Shred-Tech

Screener

Pronar 20.55gh Trommel

The MPB 20.55gh Trommel Screen is a deluxe screening workhorse that consistently and effectively separates a large volume of material even in unforgiving terrain. This robust machine boasts an 18ft long 6ft diameter drum with leveling system allowing it to work in uneven terrain. Use the levelling mechanism to create drum inclination to work with even more materials. Several industries benefit from a reliable trommel screen, including food, food waste, scrap, agriculture, and more.

3r Sales

sales@3rmachinery.com

1-800-465-3214

Terex Ecotec

Screener

TXS 350

The Terex Ecotec TXS 350 three-fraction Starscreen offers high-capacity screening in a wide range of materials, including biomass, compost, green waste, topsoil, wood chips and bark.

Fitted with self-cleaning stars and sectional speed control, combined with an intuitive control system, the TXS 350 will perform in even the most challenging of applications. Designed with maintenance in mind the cassette-style screen decks design facilitates quick removal reducing downtime and increasing productivity. The machine can be powered either by the onboard genset or via an external power supply.

Aaron Lang

aaron.lang@terex.com

603-560-6931

Vermeer

Screener

TR6500TX

The TR6500TX trommel screen is a feature-rich mobile screener, giving mulch and compost yards a highly productive and user-friendly machine that can be set up, repositioned and operated by a single person. It builds on the Vermeer legacy of trommel screens with tried-and-true features and new innovations that are designed for jobsite efficiency, application adaptability and ease of maintenance.

Ted Dirkx

tdirkx@vermeer.com

Viably

Screener

Komptech Multistar XL3

This efficient, 80 kVA, multi-fraction screening machine is engineered to bring added versatility to mid- and large-volume mulch, soil, and compost producers.

Viably Compost Expert

hello@thinkviably.com

720-890-9090

WINDROW TURNERS

EDGE Innovate

Turner

EDGE FTS75 Mulch Master

The EDGE FTS Mulch Master sets new standards for the handling of organic materials like mulch, compost, and soils. This portable feed stacker / windrow turner is a multiple purpose unit that combines efficient stockpiling, turning, and blending to optimize biological decomposition of organic materials. With a high-torque turning drum and optional irrigation system, the EDGE FTS Mulch Master ensures aeration, moisture control, and consistent material quality.

Lee Williamson

lee.williamson@edgeinnovate.com

205-777-9987

Frontier

Windrow Turner

Frontier TB18

Windrow Size: 7’ Lowered – Hydraulically Raises to 9’ by 18’ wide

Drum Speed: 460 – 515 (depends on tractor RPM)

Tractor Requirements: 350-400 HP required IVT or CVT TRANS

1000 PTO Speed

Five Hydraulic outlets

Wayne Howe

frontiersales@outlook.com

503-559-0864

Vermeer

Windrow Turner

CT718

The CT718 compost turner sets new standards for efficiency, productivity and ease of operation. Operator comfort and efficiency have been enhanced — including new controls, an easy-to-read control display, along with side- and rear-view cameras. Plus the main frame with a lower machine height for better transportability.

Ted Dirkx

tdirkx@vermeer.com

SUPPORT & SITE EQUIPMENT

Green Harvest Solutions

High-Density Packaging/Compacting equipment- Orkel Baler

2026 Orkel Denz-X Pro

Take your packaging to the next level with the Orkel Dens-X Pro — the new generation of the world’s leading high-density baler-wrapper combination. Built for strength, speed, and smarter operation, the Dens-X Pro delivers outstanding performance across a wide range of materials — from wood fiber to compost, bark, wood chips, and anything in between, The Dens-X Pro achieves unmatched throughput — reaching up to 70, one ton bales per hour under normal conditions.

Ross Vehmeier

Ross@greenharvestsolutions.com

815-275-4345

eFACTOR3

Windsifter

Westeria AirBasic

The AirBasic brings the advantages of Westeria’s proven windsifting technology to a small, mobile machine. It is available in various options to ensure optimum separation results at any site. The material can be fed from any direction (180°). The AirBasic features a patented adjustable and precise nozzle system that works much more efficiently than comparable products on the market.

Wherever waste of various kinds, such as construction waste, compost, household waste, slag, or even scrap is separated, the AirBasic shows its full capabilities.

Advantages:

Patented adjustable and precise nozzle system

Flexible integration with other systems

98% guaranteed separation result

Alyssa Barbour

abarbour@efactor3.com

704-495-5438

https://efactor3.com/products/waste-recycling-equipment/windsifters/

Papé Machinery

Excavator

John Deere

From material handling and earth moving to digging and demolition, the excavator plays an important role on many construction and forestry sites. Available in both wheeled and tracked models, operators can choose from highly specialized models to increase productivity on specific projects.

At Papé Machinery, you’ll find a variety of makes and models designed to meet the needs of your unique worksite. John Deere is known for making reliable excavators that are built to last. And regardless of model or excavator class, you’ll see your investment pay off year after year.

Ted Pumphrey

tpumphrey@papemachinery.com

669-235-2842

Papé Machinery

Wheel Loader

John Deere

Wheel loaders allow operators to easily scoop, transport, and distribute large amounts of earth and other materials. They play a vital role on most construction sites, drastically increasing worker productivity and efficiency. That’s why they can be found everywhere from mining operations to construction and leveling projects.

At Papé Machinery, we deal in only the best, offering a wide selection of top-of-the-line John Deere equipment. From large wheel loaders to mid-size wheel loaders, there are plenty of options for your business. Learn more about the different machines we carry to find what meets your needs.

Ted Pumphrey

tpumphrey@papemachinery.com

669-235-2842

Reotemp Instruments

Site Equipment

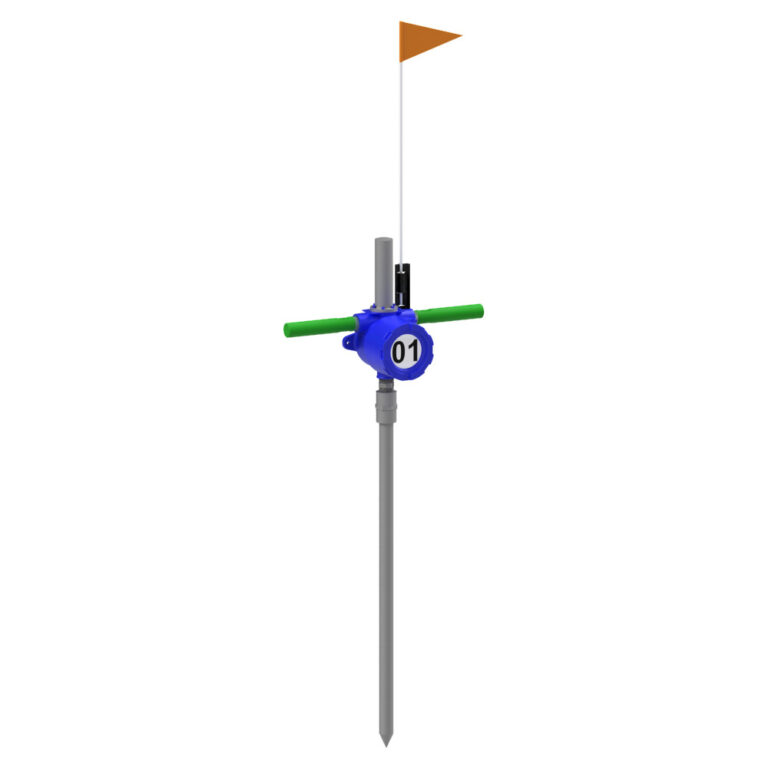

CompostWatch Cloud Eco Probes

Introducing CompostWatch Cloud: Reotemp’s latest wireless compost temperature monitoring system for windrow-based sites. Monitor your compost piles conveniently from your cell phone, computer, or tablet. Our system offers affordability and reliability with industry-trusted wireless EcoProbes

Emilo Cervantes

ecervantes@reotemp.com

909-503-6007

Shred-Tech

Site Equipment

Pronar 24/1g

The MPT 24/1g mobile stacking conveyor is for customers looking for a conveyor designed with low operating costs, lower weight and compact dimensions in mind. Move up to 400 tons of material per hour and stack material up to 35-feet high. The MPT 24/1g offers low fuel consumption and works perfectly in line with a shredding or screening unit.

3r Sales

sales@3rmachinery.com

1-800-465-3214

Sustainable Generation

Site Equipment

SG SOLAR® POWER w/ SG COMPOST CONTROL™

SG Mobile® System using SG Solar® power. Fifteen-meter system size, powered and controlled by a completely off-grid solution. System controls accessible from any location via internet.

Brett Hoyt

brett.hoyt@sustainable-generation.com

303-601-3404

Totemic Sustainable Solutions

Compost Monitoring Equipment and Technology

CompostManager Probe

The CompostManager Probe is a comprehensive solution designed to revolutionize composting practices by simplifying process management and ensuring compliance with industry standards. Developed from years of research and over a million data points, it combines state-of-the-art hardware with advanced software to provide real-time analysis of key composting parameters—temperature, moisture, oxygen, and carbon dioxide.

This easy-to-use system delivers precise recommendations on when to turn, irrigate, or leave compost untouched, optimizing decomposition and maximizing output quality. With cloud-based data storage, businesses gain valuable insights and verifiable records, making CompostManager an essential tool for sustainable composting operations. Composters have been using the CompostManager since 2005!

The hand held CompostManager Probe can be used to monitor several dozens of windrows. Typically monitoring 4 locations per windrow and spending 60 seconds per monitoring location.

Please ask us about our program to “try before you buy”!

Thomas Gilardi

tgilardi@totemicsolutions.com

804.334.7873

U.S. Pride Products, LLC

Site Equipment

Tree and Stump Splitter, U.S. Pride Products, H.F.800

The HF-800 2 Speed model is essentially the same as the HF-800 with the addition of a 2 speed motor. This allows the splitter to automatically shift between speeds as needed. Some large skid loaders, and other machines, don’t always have enough hydraulic flow to turn the single speed HF-800 efficiently in tough material. By utilizing a 2 speed motor, machines with lower hydraulic flow can still split the big stuff productively. This Two speed HF-800 can be run on any carrier from skid steer or wheel loader to the largest excavator.

Charlie VanDusartz

charlie@usprideproducts.com

715-760-0907

Viably

Separator

Viably Eliminator

The Viably Eliminator is a diesel-hydraulic, track-mounted multi-fraction separator designed for high-volume material processing using advanced air separation. An integrated two-station picking line, adjustable destoning belt, and ferrous separation provide effective control across multiple output streams.

Viably Compost Expert

hello@thinkviably.com

720-890-9090